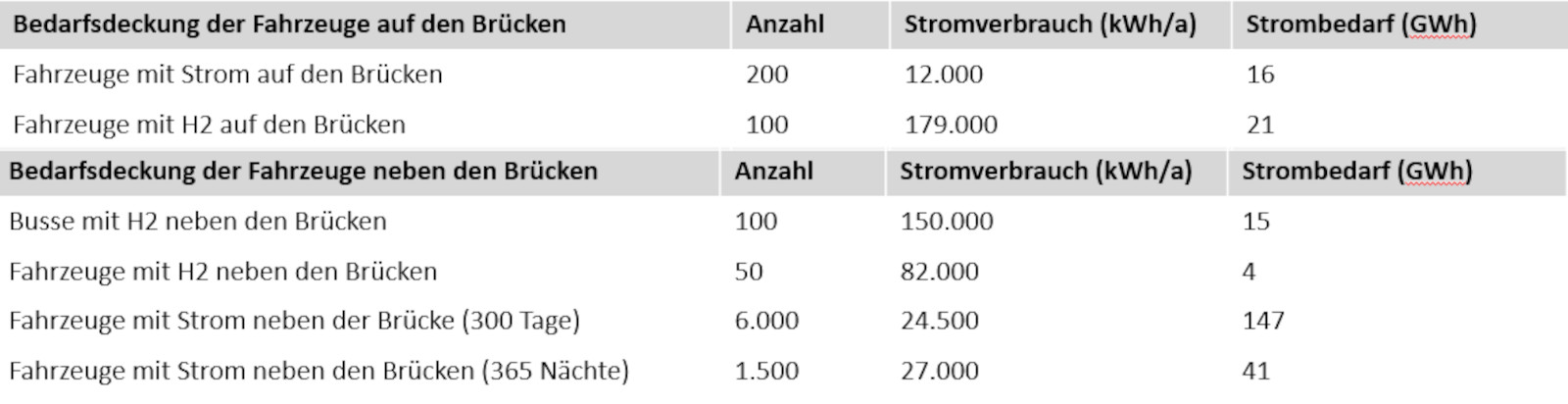

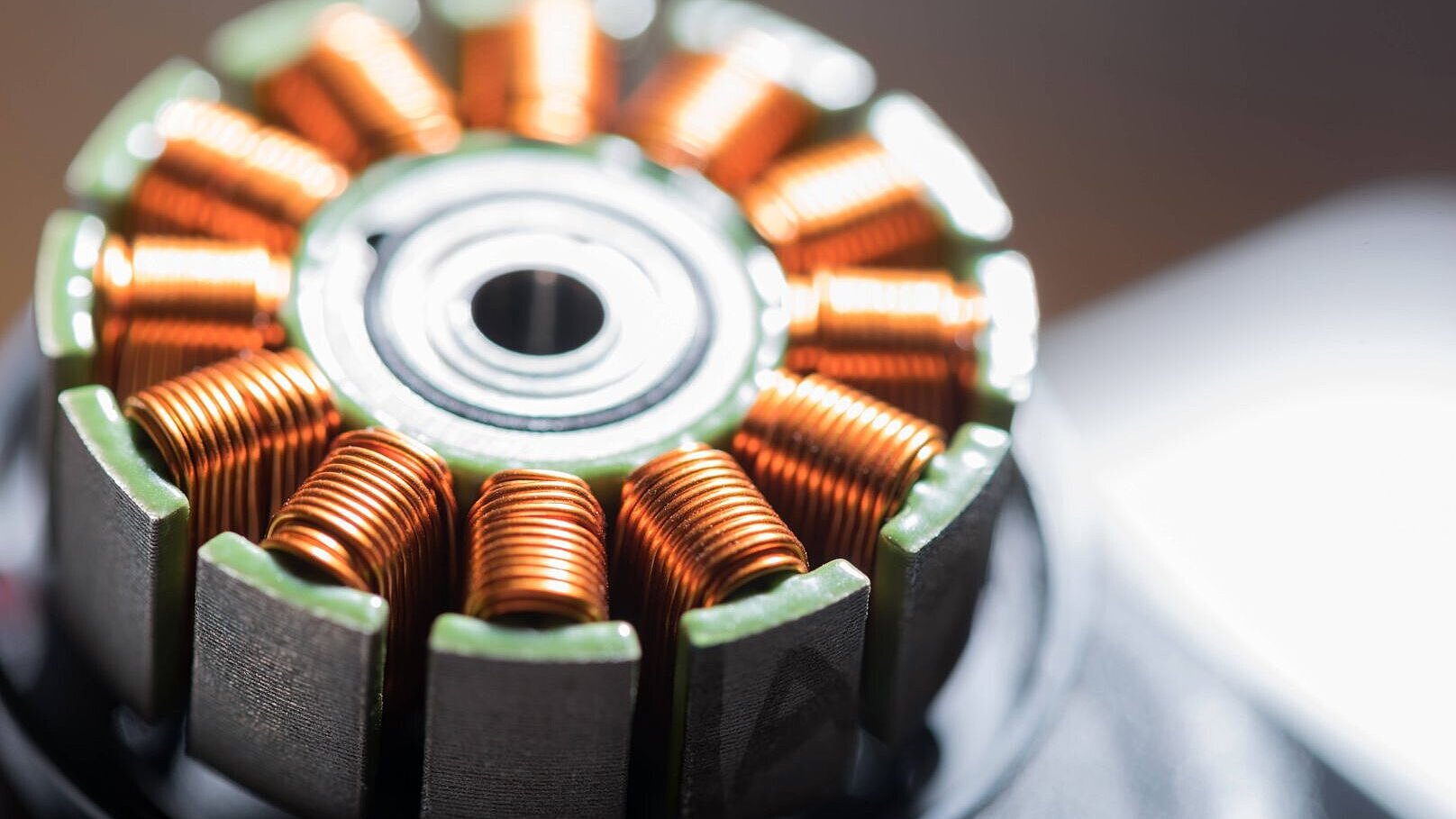

Content: The bridge fleet is particularly environmentally friendly because the most sustainable solution is always chosen for the propulsion system, the selection of building materials and the frame construction.

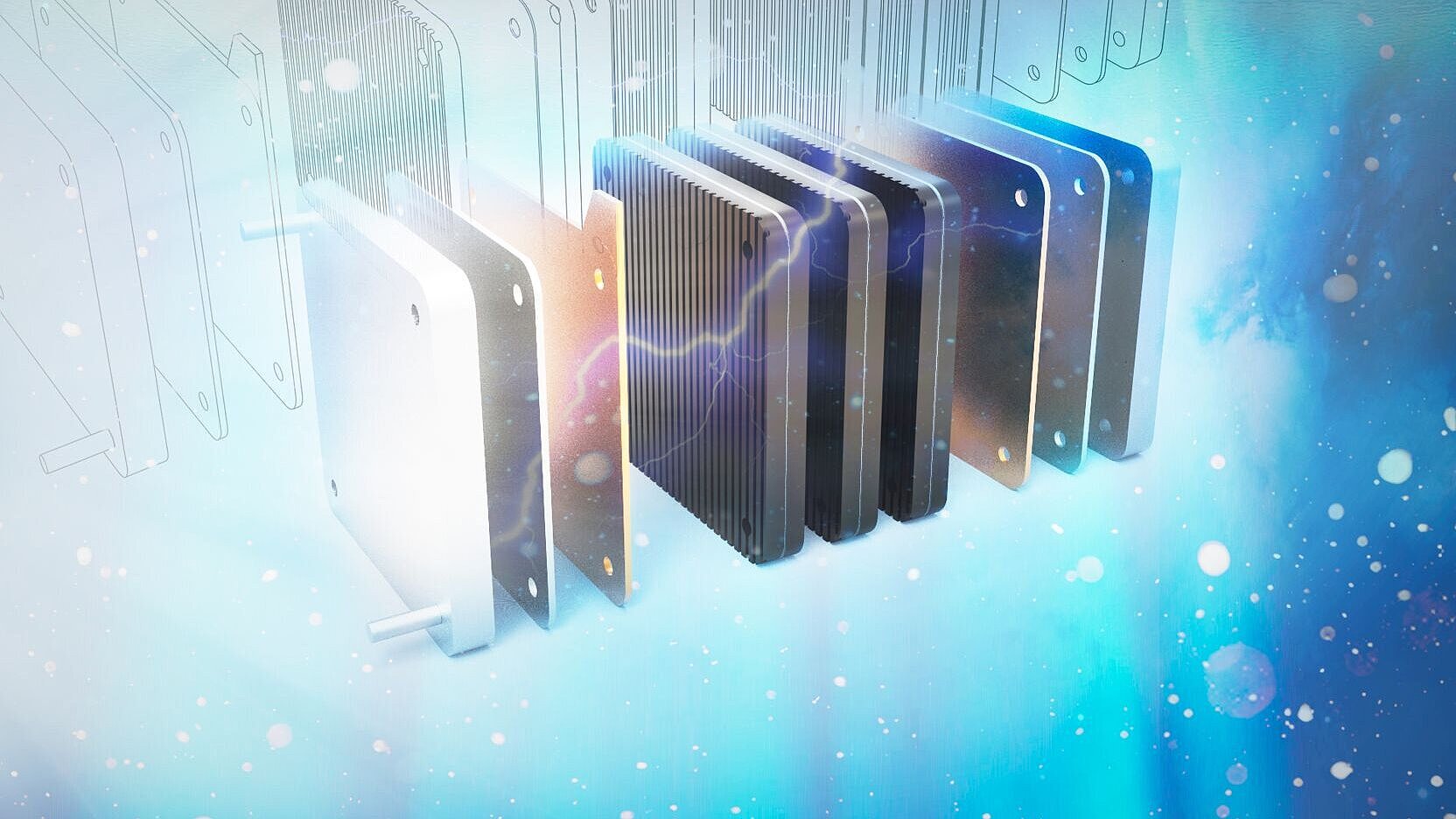

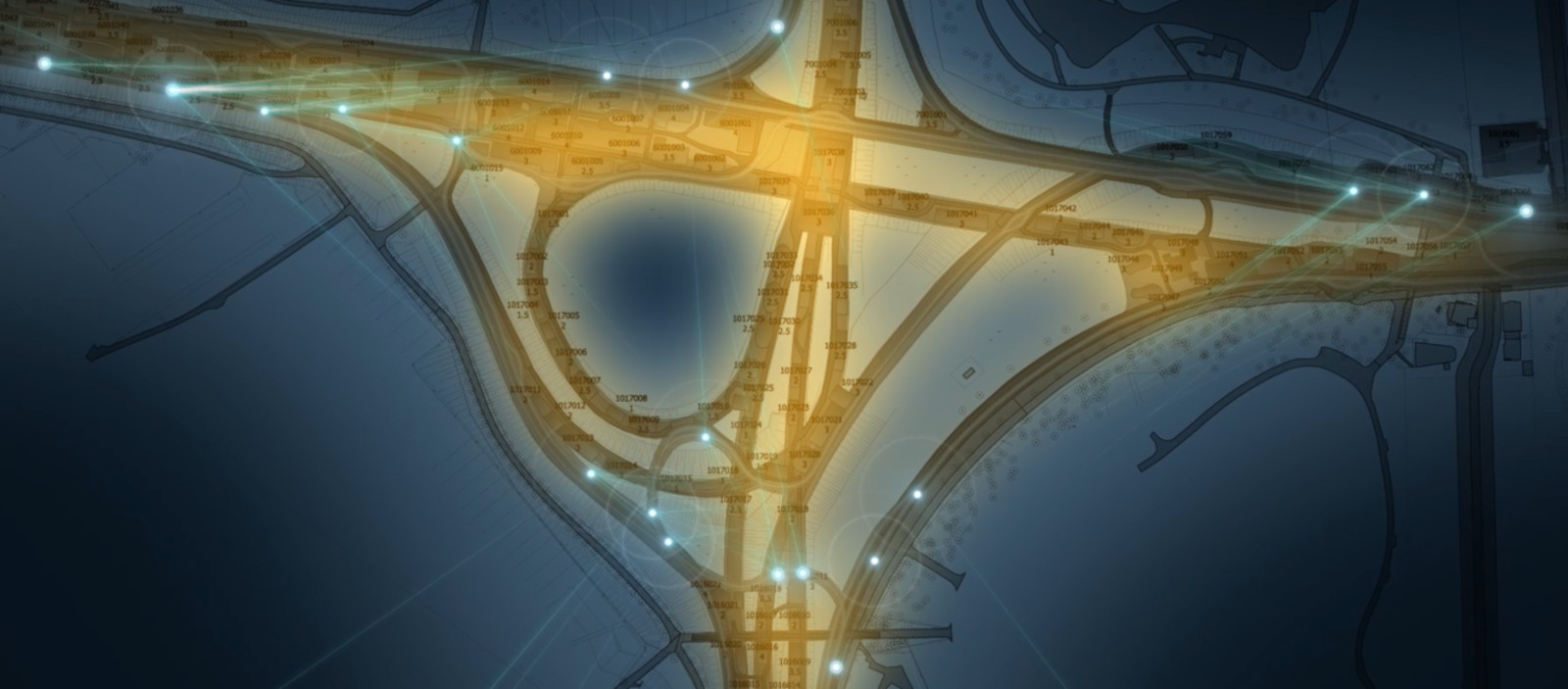

There are battery-electric and hydrogen-electric vehicles on the bridges. The required refuelling infrastructure is not only provided by the bridges for their own vehicles; rather, e-cars can also charge their batteries down on the roads, and hydrogen vehicles can fill their tanks at the hydrogen filling stations located on the seven outer arms of the bridges as well as on the bridge ring.

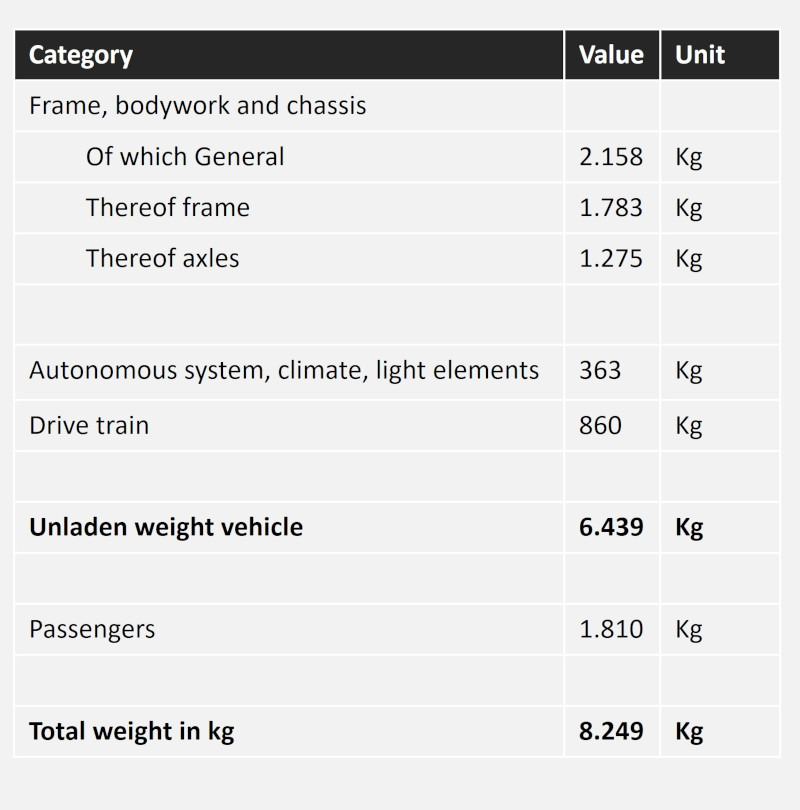

The second major lever for the sustainability of the fleet is to save material through structural optimisation, a significantly lower number of vehicles and the long life cycles of the vehicles.

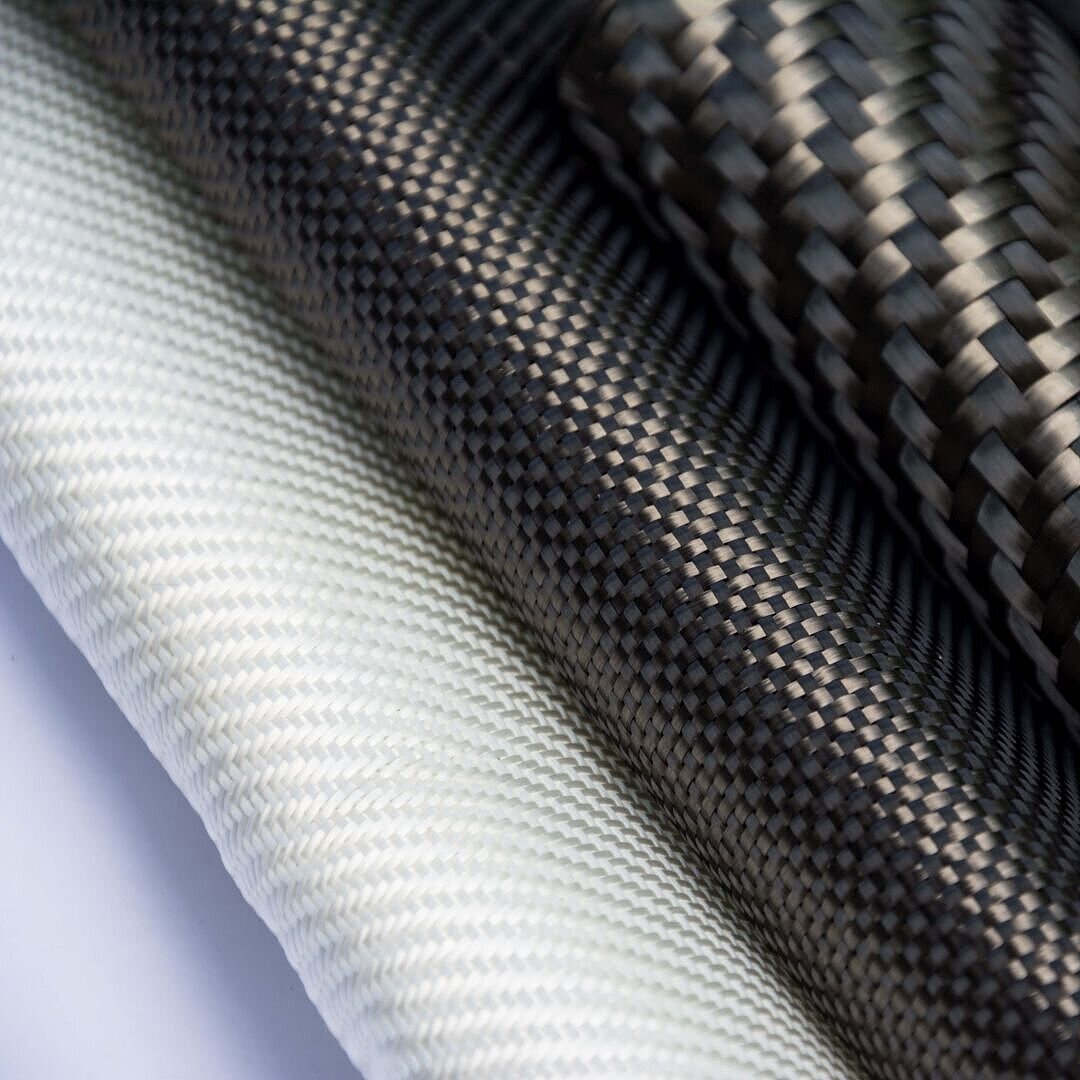

Furthermore, in the selection of materials, emphasis is placed on sustainable building materials or, where possible, on renewable raw materials.