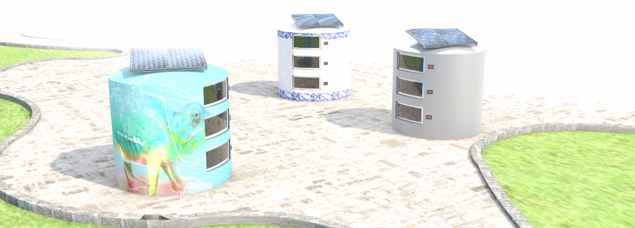

The cleaning process begins on site in the collection machine

It will be possible to put the used take-away containers and tableware into small, separate mini dishwashers, which are self-contained units, because when the sliding window is opened, no other dishes with food remains must be seen or smelled.

Once a mini dishwasher has been filled with its containers, cutlery, glasses etc. through the window, the window closes, the mini dishwasher is moved one place further from the roundel (so that the next, still empty mini dishwasher comes to stand behind the sliding window) and then all take-away containers etc. in the mini dishwasher are briefly filled with hot steam and then irradiated with UV light to kill germs. The mini dishwasher carries the water for the steam with it and receives the electricity via contact surfaces with the electronics in the Rondell core.

This is not yet the actual cleaning, but merely serves to ensure that when the containers are collected and taken to central cleaning sites, they do not arrive there germ-ridden and fungus-ridden.

As soon as all the mini dishwashers have been filled in all three rondels of the machine, the collection machine sends a signal to a vehicle that -driving autonomously- comes and collects the three inner rondels: The easiest way to do this is to have half of the vending machine housing consist of doors that open, the rondel core together with the three rondels and their mini dishwashers is lifted by rotating trolleys and transported into the car, from which a new empty rondel unit comes and takes the place of the old one in the collecting vending machine.

The vehicle brings the rondel units to the railing of the FES, and after the containers have been centrally cleaned in accordance with regulations in a facility specially built there, they are returned to the catering trade on the bridges according to the quantities ordered.

The prerequisite: The consumer plays along and fills the mini dishwashers just like his own at home: without food leftovers or foreign objects - which the collection machine, however, also registers with sensors and can assign to the respective bridge card of the user - and, if necessary, book a fine via deposit deduction.